In the industrial corridors of Penang, Malaysia, a sudden structural failure can lead to significant operational downtime and safety hazards. This case study examines the technical root cause analysis (RCA) of a chimney collapse at a mattress manufacturing facility during a severe thunderstorm.

Our forensic engineering team was commissioned to determine whether the failure was a result of environmental extremes, human intervention, or long-term structural degradation.

The Incident: Environmental Trigger vs. Structural Vulnerability

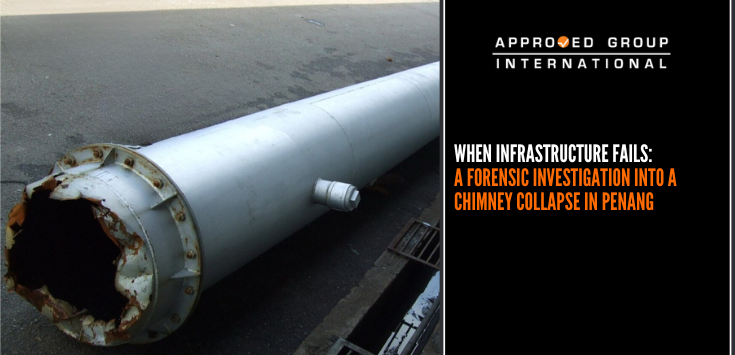

At approximately 0230 hours, the upper section of a 20-meter chimney collapsed during a heavy storm. The structure, which served dual fire tube boilers, fractured near the connecting flanges approximately 10.5 meters above ground level.

1. Site Examination & Damage Analysis

A thorough scene investigation revealed that the collapsed section had impacted the main factory roof, damaging corrugated metal panels, scaffolding, and sprinkler systems.

Fracture Point

The break occurred just above the metal platform surrounding the chimney.

Physical Evidence

Distinct impact dents were noted, along with severe corrosion at the point of fracture.

Support Systems

Supporting metal cables and tether points showed no signs of mechanical cutting or tampering, ruling out human intervention.

Technical Discussion: The Role of Wind and Corrosion

To provide a definitive conclusion, our forensic engineers analyzed weather data from the nearby Butterworth Air Base and performed detailed metallurgical measurements.

Wind Speed Analysis

Weather records indicated fluctuating wind speeds peaking at 18.5 km/h earlier in the night, with a southeast wind direction at the time of the collapse that matched the chimney’s final resting position. While these speeds are categorized as a “gentle breeze” on the Beaufort scale, they likely acted as the final trigger for a compromised structure.

Metallurgical & Thickness Testing

Our team conducted a comparative analysis of the sheet metal thickness at the point of fracture versus the upper exhaust cone.

| Position | Adjusted Fracture Thickness (mm) | Adjusted Exhaust Cone Thickness (mm) |

|---|---|---|

| Minimum | 1.11 | 2.85 |

| Average/Mean | 1.16 | 3.325 |

The data revealed that the section where the fracture occurred was significantly thinner and weaker than the upper sections of the chimney.

Root Cause: Severe Atmospheric and Internal Corrosion

The investigation concluded that the collapse was largely due to severe rusting and corrosion of the sheet metal.

Internal Degradation

Severe rusting covered the entire inner surface of the collapsed section, with several spots where corrosion had completely penetrated the metal.

External Moisture Trapping

The fracture point was located where the chimney was welded to a metal platform. Over time, rainwater collected on this platform, accelerating external oxidation.

Maintenance Deficiencies

Records indicated the last major welding and painting works were conducted over three years prior to the incident, with no routine inspections performed since.

Forensic Engineering Conclusion

The collapse of the industrial chimney was caused by a combination of structural weakening through severe corrosion and the triggering force of strong winds during a storm. Our analysis suggests that even without the storm, the chimney had reached a state of critical instability where failure was inevitable without immediate intervention.

For industrial operators in Malaysia and Singapore, this case highlights the critical importance of regular structural integrity audits and protective coating maintenance for exhaust systems exposed to tropical weather conditions.